This is an update by SV8YM to the recent mod he uploaded to mod.dk. So I have to post it for anyone that could be interested.

“After my first experiences with this problem, I had proposed a simple preventive measure, consisting of adding a gate series resistance to the driver unit, which apparently suffers from instability with destructive results in many cases.This update is the result of further study of the problem. It attacks the problem in a more efficient way,taking more measures to reduce the instability but also taking measures to prevent the destruction of the driver unit.The update consists of two parts, the first about improving the original modification, and the second about taking extra steps to ensure better stability and protection of the transistor in the driver unit. One can perform just the first part which is very simple. The second part is quite a bit more complicated and requires lifting the PA PCB and performing more alterations and additions to the circuits - but it offers considerably more safety.

PART 1: IMPROVING THE FIRST MOD'S EFFECTIVENESS

The first mod required the addition of a 10 Ohm resistor in series with the input (gate) of the PD55015 LDMOSFET in the driver unit. After studying the circuit's behaviour and experimenting, I finally , changed the resistor’s value to 1 KOhm (see schematic below) which offers much more stabilising action with just a modest decrease in power output (~5%). So, if you have already done the first mod, change the resistor to 1000 Ohm. If you haven't yet done it, refer to www.mods.dk for the full description of the first mod,but use an 1000 Ohm resistor , instead of 10 Ohm. Resist the temptation to tamper with the service menu to compensate for the small ~5% loss in output power – it's really not worth it.

PART 2: ADDITIONAL PREVENTIVE MEASURES

The second part attacks the problem from different angles. It requires considerably more effort and skill. This part is for the more experienced technicians, so detailed instructions (e.g. "lift the PA PCB by desoldering... and then..." etc., will not be given here. Please be extremely careful.

1) Modification of the drain - gate negative

feedback network of the driver unit

Lift the PA PCB and remove the driver unit. The drain - gate negative feedback network flattens the gain vs frequency response of the broadband driver amplifier stage. It uses a capacitor (C101,10nF and a resistor (R102, 100 ). Change the capacitor to 0.1 μF, 50V. This lowers the range of frequencies for which the network provides negative feedback, stabilising the amplifier there also. Apply a thin film of silicone grease to the heat sink's surface and tighten the driver unit's fastening screws well when replacing the driver unit.

2) Addition of an extra bypass capacitor

This part requires adding an extra tantalum bypass capacitor across C305 (470 F, 16V PA UNIT). Locate the capacitor's leads (see photo and schematic diagram) and solder a 47 F / 35V tantalum capacitor across the electrolytic. Observe the polarity!!

3) Addition of a driver unit protection fuse

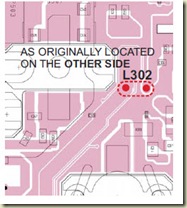

Adding a fuse to the 13.8VDCline feeding the driver transistor's drain improves the chances that even if the instability occurs, the transistor will survive. (There won't be any fireworks and smoke, in any case!). Locate L302 on the PA UNIT (see the schematic diagram that follow for diagrams and photos). Unsolder it and transfer it to the of the PAUNIT (as shown in the service manual), soldering only the lead that connects it to the node with C305 and L301. Then solder an 1.5 A, fast-blow 20mm glass fuse to the free lead of L302 in the way shown in the photo, soldering the other end of the fuse to the PCB trace that L302 used to connect to (it's the "b" line with 13.8V on it). Use a small piece of wire to solder the fuse to the trace. Don't locate the fuse elsewhere using long wires! Do it exactly as shown. Lay the fuse flat on the PCB.Use a small piece of thick paper or plastic sheet to insulate the end of the fuse soldered to the free lead of L302 from the PCB trace under it. After you have finished, cover the fuse with a piece of electric tape to prevent shorting the 13.8V line when replacing the rig's covers.

FINALLY, 4) Lowering the idle current of the driver unit

In order to lower the gain of the class A driver stage, also reducing

its thermal burden without seriously affecting its linearity at the RF

drive level used, we can lower the idle current via the service menu. The service manual procedure sets the idle current of the driver unit at 1A. Reducing it to 0.6 A produces no ill effects on linearity (as measured in a two-tone test in SSB). Follow the procedure at page 4-3 of the service manual, "transmitter adjustment". Set the current at 0.6 A as per the instructions and exit the service routine.

This concludes the mod. Good luck! Enjoy using your IC7000!”

The diagrams that follow refer to the fuse addition